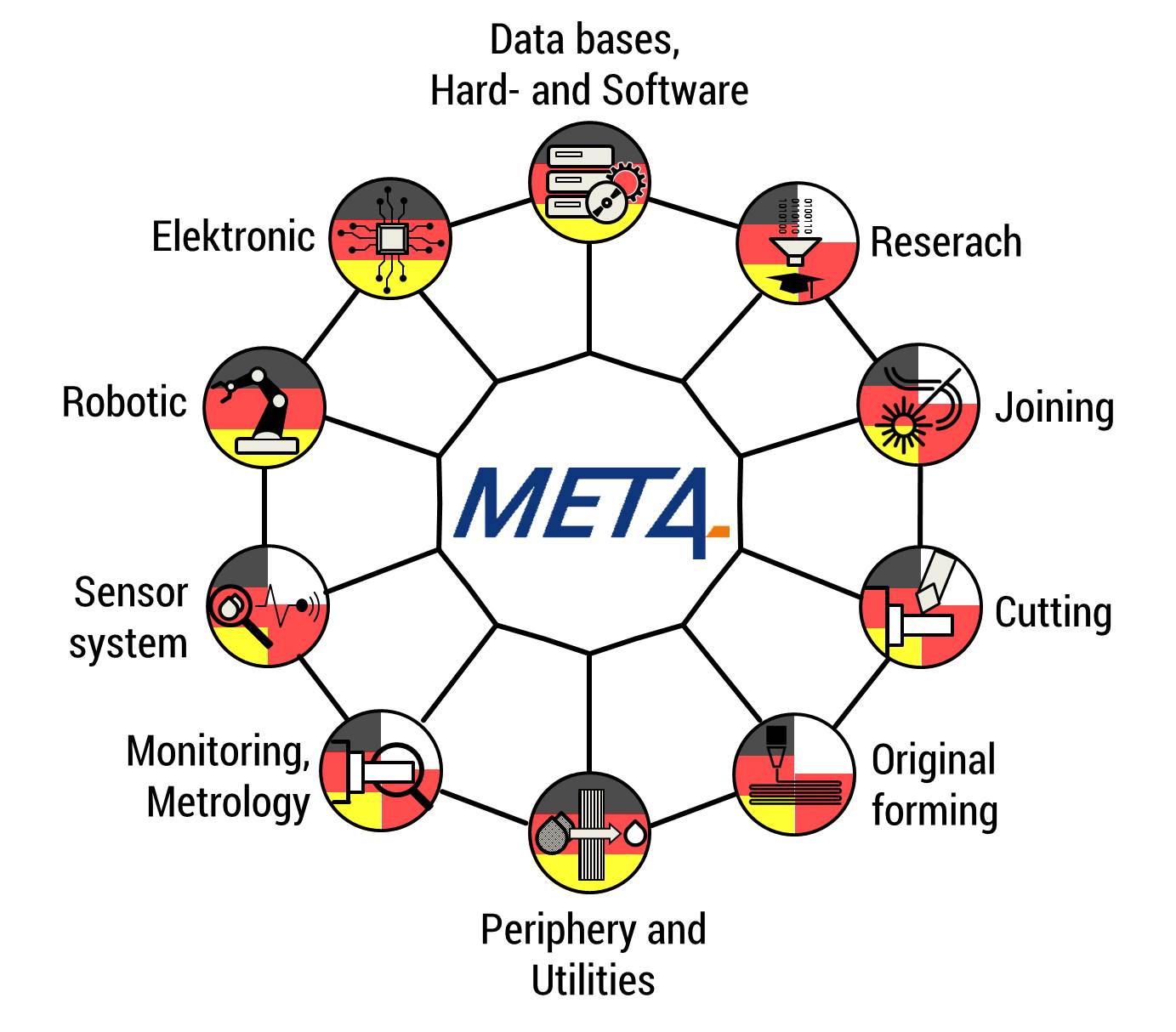

Goal and Concern

The Network "META - Manufacturing 4.0 durch Entwicklung und Transfer progressiver Automatisierungslösungen" supports small and medium-sized enterprises (SME) from the field of manufacturing technology in monitoring their processes and products by developing smart monitoring and automation solutions. By bundling the most diverse competences, experts and interests in the fields of automation and production technology as well as digitalisation and networking, relevant process and plant data are collected from problem-oriented (sub-) processes and processed into metadata by means of intelligent information compression.

These serve to monitor, evaluate and optimise the respective products and services as well as the associated machines and processes. Besides the available resources, integrity and acceptance by the company are essential conditions for the strategies and solution approaches to be developed. Furthermore, META aims to facilitate access to the content of Industry 4.0 for these SMEs and to harmonise it with their business and innovation processes for long-term value creation.

Development lines

The joint research of the META network focuses on the following six areas:

1. Control Loop Performance Monitoring

In the field of machine tools, the generation of motion required for the respective process is usually achieved by electromechanical feed axes. Their control is implemented in the form of a cascaded position control, which is a decisive factor for dynamic, resource and energy efficient production while at the same time meeting the highest quality requirements for the products to be manufactured. This leads to the conclusion that a targeted monitoring of the drive-internal control loops can make a significant contribution to increasing productivity, efficiency and process reliability. Currently, the use of monitoring methods is limited to areas with high demands on safety and accuracy or the detection of mechanical wear or undesirable process conditions. In order to counter this deficit, a wide range of innovative methods have been developed in recent years, but these need to be subjected to further practical analysis on an industrial scale. These developed approaches offer the possibility to make statements about the condition of the mechanical transmission elements up to the prevailing process forces in addition to a pure performance evaluation of the individual control loops. In the form of compressed characteristic values and meta-information, the process knowledge can thus be significantly increased without increasing the complexity of the feed axes by installing additional sensor technology. The goal within META is to increase the acceptance of the academically developed and validated methods in industrial practice by transforming them into a practical application and to benefit equally from the generated monitoring data.

2. Manufacturing process monitoring

Along the process chain from the raw part to the finished product, the production quality essentially influences the surface properties of the end product. As these have a direct effect on the product quality, a qualitative and quantitative consideration of especially the auxiliary processes is necessary to ensure a holistic process stability and quality within the production, as these have a great potential for savings and improvement due to the currently low degree of automation and monitoring. Changes in the cooling lubricant (coolant lubricant) or impurities on the component surface, for example due to incorrect concentrations or bacterial infestation in the coolant lubricant or cleaning agents, lead to changes and thus to a deterioration of the production quality. However, these only become apparent at the end of the value chain in the form of poor product quality. By recording, characterising and processing relevant parameters and data, as well as by networking and digitalising them, automated monitoring and control systems are to be developed which optimise upstream and downstream process steps and ensure various quality aspects around the auxiliary and auxiliary processes.

3. Manufacturing process control

New types of high-performance materials and the demand for customized products are leading to a steadily increasing use of abrasive waterjet cutting in industrial production. The operating principle is based on the acceleration of fine-grained cutting particles with a high-pressure water jet to supersonic speed. According to the current state of the art, jet generation is associated with heavy energy losses. However, if the particles are mixed into the cutting water before the high-pressure generation and a suspension is created, the energy losses are prevented in the previously downstream particle acceleration, as is the case with the injector jet. This opens up a completely new field of application in the high-performance sector for waterjet cutting based on the suspension principle. Of central importance for the application of the suspension jet process in the production of parts is a high degree of automation compared to conventional system technology. The lack of system monitoring up to now is regarded as a central hurdle for the introduction of the process into the manufacturing industry.

4. Manufacturing quality control

The complex manufacturing process of mechanical blasting is used for the surface treatment and quality of a product and is located at the end of the value-added chain. It addresses the issues of aesthetics, lifetime extension, cleaning or functionality of components and their surfaces, which are a decisive factor for the quality and market success of a company and its product. With an innovative further development of this manufacturing process based on wheel blasting, the prerequisites for an automated process have been created. With the derivation of process-relevant and quality-influencing parameters, a standardization and quantification of the blasting process with the focus on manufacturing and product quality is to be created, which is also to be transferable to other application-oriented and complex manufacturing processes. A further focus is the characterization of three-dimensional (blasted) surfaces, since this represents a substantial quality feature for the various applications, is a yardstick for the evaluation of blasting processes and no meaningful standardized, three-dimensional parameters are currently available. As a result, intelligent control and regulation strategies will be developed, which will be realised on the control side on the one hand and connected to upstream and downstream processes by creating open interfaces or new components on the other hand.

5. Modular Automation solutions

For increasingly complex, highly stressed components, a testing step should be directly connected to the manufacturing process chain. Thus, desired key properties of the component can be ensured directly and, if necessary, adjusted in the event of deviations in the manufacturing process within the framework of process control. The requirements for testing processes and machines are therefore not only dependent on the object to be tested, but also strongly on upstream and downstream processes and the plant engineering environment. Automated test cells must be implemented in the context of an existing plant or a plant under development. In order to meet the requirements in the context of cost and time pressure and to be able to estimate these already in an early conception (if necessary already in the offer phase), a CAE process (computer aided design, engl. computer aided engineering) is purposeful. The technological tasks can be modularized and basic designs can be provided from a portfolio. For a specific testing task (tensile test, bending test), for example, a pre-designed layout of a test cell can be used as a basis, based on a class of material (steel, light metal, plastic) and the size of the component. This test cell can be available as a mechanical construction (CAD data) together with the required electrical components (electrical design, sensors, control components) and a basis for the control program. Further modules could be, for example, linearly moved infeed/outfeed units, multi-axis motion units (robots), workpiece carriers and gripping units, each with defined mechanical interfaces.

6. Manufacturing process development

Mechanical surface hammering (OFH) is an incremental forming process for smoothing, work-hardening and compacting surfaces by continuously hitting the workpiece surface with a spherical hammer head. This gives OFH a high application potential for finishing a wide range of workpieces such as forming and injection moulding tools, 3D-printed or sintered components, turbine blades, slide bearings and vacuum chambers, and the process has been used for several years. The development of the piezoelectric OFH (PiezoPeening) has shown a significant increase in efficiency by a factor of 4 to 6 compared to conventional pneumatically and electromagnetically operated SAH systems due to the significantly higher knocking frequency compared to conventional actuator solutions (pneumatic, electromagnetic). A disadvantage of PiezoPeening, however, is the very low tolerance to positioning errors of the OFH tool or to geometric errors of the workpiece. This currently makes the use of expensive high-precision machine tools (WZM) necessary. A significant increase in profitability can be achieved if - as with conventional OFH - inexpensive but well-known inaccurate industrial robots can be used for this purpose. One solution is the force control of the piezo peening process, so that the robot can compensate for geometric and positional errors, thus achieving the necessary process reliability for industrial applications.